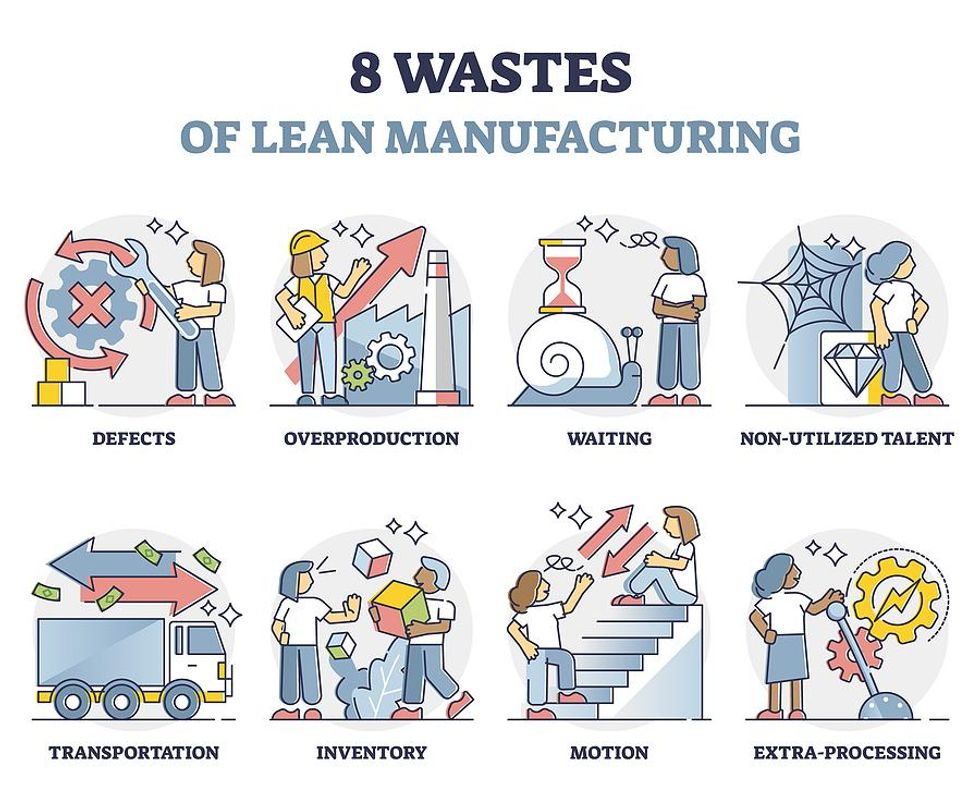

To begin, what are the lean wastes?

TIM WOOD — Who Is This Guy?

Bigstock

- Time

- Inventory

- Motion

- Waiting

- Overproduction

- Overprocessing

- Defects

Time — It’s Ticking In Your Head!

Bigstock

Do engineers waste time? NEVER!!! Are you sure? How long did it take you to look up a part number for your last project? Have you spent hours on the internet combing for the perfect transformer? Did you rework the drawing because it was missing information? All of these take time.

Time is an engineer’s best asset. With any project, more time is always preferred. Despite our best efforts, everything has a deadline, and you will be out of time. So why do things take so long to accomplish?

Much like production, everything an engineer does has a process—formally or informally. If your process requires you to do unnecessary tasks or wait in a queue for information, it all takes away from our time.

Review what it truly takes to complete a task versus the total time to complete an action. The difference is your opportunity. How can you make tweaks or eliminate wasteful tasks to improve your time?

Inventory — How Can Engineering Have Inventory?

Bigstock

In the classical sense, engineering typically does not have dozens of parts on their desks or stacks of products on the shelves.

How many projects are on your desk needing your attention? How many drawings need revisions from production markups and changes? Do you have software programs written for customers? How many documents need approval?

Each of these “soft” products is inventory. Thinking broader, any accumulation of work ahead of you is your inventory. The more projects, tasks, and activities on your desk, the higher the inventory for you as a worker. How do we deplete inventory?

For administrative tasks, plan a time every day to work through the tasks. Approvals in the ERP system are complete at 9 am each day. Drawing reviews are scheduled at 2 pm on Tuesday. Some days you may have five or more of these tasks, and other days you may have none. Scheduling your time to complete these tasks is essential.

Larger tasks can be managed the same way. Use large blocks of time with no meetings to eat the elephant one bite at a time. Make sure you take action weekly on these tasks to prevent overwhelming inventory numbers.

Finally, do you need to do this task at all? Delegate or eliminate the work. Is it necessary? Am I the right person to do it? If the answer is no, get rid of it!

The goal is to minimize your inventory and focus effort on where you add value.

Motion — Do I Need To Leave My Chair?

Bigstock

Unlike production where work may be completed in different physical locations, engineers typically work in their station and may even be sedentary. So how do I eliminate motion?

Do you walk to meetings twice a day in a different part of the building? Do you need to cross the room to use the copier? Are you required to deliver signed documents to another member of the team? Is your telephone or headset across the desk?

Motion is trickier in an office setting; however, with some creativity, you can eliminate the waste. Can my meetings be scheduled back to back to keep from leaving your office as often? Do I rearrange my desk for better optimization of my mouse, keyboard, phone, etc.? Think outside of just walking back and forth.

Waiting — Why Can’t I Get Any Answers?

Bigstock

How often do you need to wait for a customer to agree to a specification? Does accounting owe you a price for the transformer you are quoting? Is your boss sitting on the drawing approval needed to submit to the customer?

Each time an engineer waits for an answer or another process, this leads to waste. You cannot proceed without someone else’s action. You rely on someone’s actions to complete your own.

How do we eliminate waiting? It is inevitable to be waiting on someone. Can you send an email ahead of time asking for their help to approve the drawing? Could you call your customer asking for clarification versus sending an email? Could you walk something to the accounting department asking for their attention?

Find ways to eliminate or minimize wait times. Take proactive actions to ask for assistance. Ensure all the necessary information is available to the next person in the process. Look for those subtle little items that add up over time.

Overproduction & Overprocessing — Why Do More Than You Are Asked?

Bigstock

Both of these wastes involve doing more than what is expected. Throughout my career, I have been encouraged to under-promise and over-deliver. Why?

Of the wastes, I would say these two are the most difficult for engineering. We are expected to (over) produce products that exceed customer expectations.

Experience will tell an engineer when enough is enough. Over-designing a solution is a waste. Making more drawings than are necessary is a waste. Look for opportunities where you are handling the same item more than once. Can I do both tasks at the same time?

Be careful of the trap of tinkering with a project simply because you have time. If your work is complete, meets the need, and is robust, stop. Continuing to tweak is an example of overprocessing. Learn from your mentors what finished looks like!

Defects — I Hate Doing Something Twice…

Bigstock

Defects are an enormous opportunity for anyone to eliminate wastes! Who likes doing the same task twice because it was wrong? If an engineer needs to do rework, the results are wasted.

Similar to the goal of “zero” safety incidents, engineers need to strive for perfection. This goal is philosophically correct, and reality shows our human side. Mistakes will occur.

How do you eliminate these defects? If you make a mistake, begin by correcting it, and follow up with changes to keep the mistake from returning. Write a procedure, make a checklist, and educate yourself (and your team) to prevent the error. When you have “extra time,” check your work. We all get tunnel vision on projects, so taking another step to verify your efforts is valuable!

When mistakes occur, learn from them. Do not swipe them aside as a trivial element of your work. Take time to make improvements to eliminate the chance of error in the future. We all make mistakes… Some of us learn to keep from repeating them repeatedly.

Is TIM WOOD My Friend?

Bigstock

The concept of eliminating wastes is paramount to a lean journey or continuous improvement. Look around every aspect of life, and you will observe wastes. Knowing what wastes look like is the first step. Your best opportunity is to find ways to eliminate them from your work. Make something better, eliminate an unnecessary step, error-proof your processes, and make things better.

So is TIM WOOD my friend? For years, the answer was no. I had no time for him in engineering because he worked in production. Now that I see him clearly, I embrace him and use him to make me, my team, and my company stronger.

YES — TIM WOOD is my friend!

- The Top 5 Interview Questions For Engineers - Work It Daily ›

- How Salespeople And Engineers Can Work Together - Work It Daily ›

- Revision Control Is The Foundation Of Any Engineering Effort - Work ... ›

- Continuous Improvement: Benefits, Tools, And Techniques - Work It Daily ›

Bigstock

Bigstock Bigstock

Bigstock Bigstock

Bigstock